When you need copper plating, look no further than out team at Advanced Plating Technologies. We are your premier copper plating company, providing superior finishing solutions that meets the needs of an array of industrial applications.

The Copper Plating Process Involve

The process of copper plating involves the deposit of a copper layer onto different metals for decorative and functional purposes. Using copper as a plating element, you can achieve a satin, glass, semi bright, polished or dull finish. It is applied as a coating for metals used in industries ranging from automotive to medical. The chemical element copper possesses various valuable characteristics. It is tough, non-magnetic, antibacterial, and has high electrical conductivity and thermal conductivity.

Copper plating is an electroplating process in which electrical current is leveraged to add a copper layer onto the base metal. Copper plating is often applied to many types of metals, including aluminum, gold, and silver. It is also deposited onto plastic. When applying copper to iron-based metals, these metals need a base coat of nickel because copper does not apply very well onto a passivated surface.

The material is first cleaned to prevent imperfections when plated. The process then continues with an electrical current passed through a copper salt electrolyte solution. With the addition of two terminals in the solution and the connection of the terminals to a supply of power, copper atoms are placed onto the metal as electricity moves through the circuit.

Applications for Copper Plating

As one of the most commonly used finishing metals, copper plating is used for a range of applications, including:

• Surface preparation for plating with silver or nickel

• Medical and laboratory equipment because of its bacterial resistance

• Large aerials placed under railways because of its leveling and bright properties

• Refurbishing worn down items such as pans and pots

• As a superb conductor, EMI (Electro Magnetic Interference) and RFI (Radio Frequency Interference)

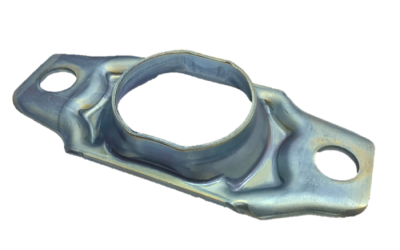

• Aluminum wheels because copper plating produces a bright finish and evens out surface imperfections

• Coins manufactured with steel with a copper layer added.

For more information about the copper plating services we offer at Advanced Plating Technologies, call us today at 414.271.8138, reach us through our contact form, or request a quote.