Industrial oxygen finds many applications. Companies employ it in medical treatments as well a production of various chemical processes. oxygen cleaning companies provide certain services to raise the level of cleanliness. They make certain that instruments employed and other devices employed in an oxygen rich environment where levels of purity are high, are safe.

What Is Oxygen Cleaning?

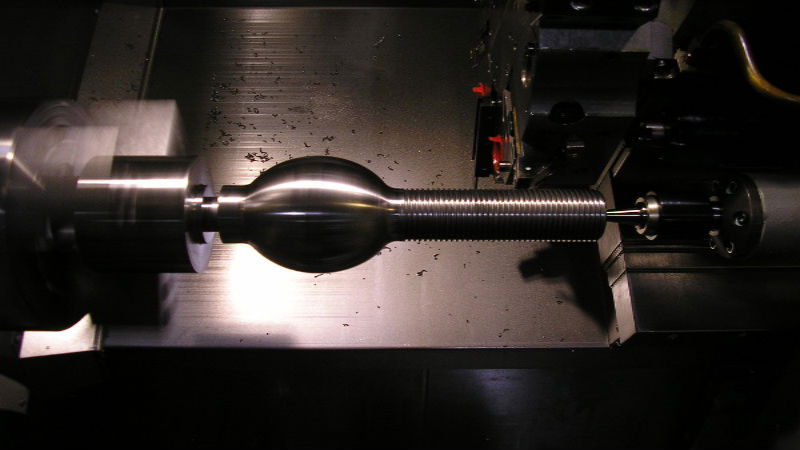

At its basics, oxygen cleaning services provide surface preparation to materials and devices intended for a certain type of environment. The items requiring surface cleaning may be fittings, gauges, hoses, tubes and valves.

This method of cleaning addresses the potential issues rising for instruments and other equipment intended to operate in an oxygen-enriched environment. The cleaning process may also be employed for cleaning the surfaces of items that are employed in high purity and oxygen processes.

As in any type of cleaning, the operator or technician prepares the component or instrument for such environments or processes by removing a variety of substances or contaminants. The most common ones are:

- Dirt

- Dust

- Fiber

- Oils

- Paper

- Waste

- Sand

- Solvents

- Weld slag

ASTM G93 includes these categories of contaminants but also includes into two other types of contaminants: organic and inorganic. Typical metals that may be cleaned of these contaminants by oxygen cleaning companies are copper, low carbon steel, stainless steel and titanium. Various alloys of these metals and others are also oxygen cleaned if required.

The Need for Oxygen Cleaning

The reason for doing so is simple. Failure can result in the creation of a situation that is potentially hazardous. The contaminants contain a variety of lingering hydrocarbons and particles. In a regular environment, these are harmless. In an oxygen-enriched atmosphere, they are capable of bursting into flames. The friction produced when a part is improperly prepared reacting with the higher oxygen content in the room (or process) not only hinders normal performance of the component or instrument, but also provides the ideal conditions for auto ignition and an explosion.

Factors Considered by Oxygen Cleaning Companies

Such potential for destruction demands fabricators dictate very high levels of product cleanliness for any item working within such an environment. The company must pay close attention to various factors involved including:

- The alloy or other metal to be cleaned

- The level of cleanliness the customer requires

- The specific shape of the component

- The configuration of the part

By understanding what is involved and the specifications, oxygen cleaning companies can implement procedures that will assure the customer they have completely removed all the surface impurities.