It is increasingly important for Original Equipment Manufacturers to find contract manufacturers to complete specific aspects of product design and development. With the advanced technology used in most equipment today, choosing specialized companies rather than trying to complete sophisticated and complex operations in-house simply makes more sense.

One of the specialized services typically outsourced to contract manufacturers is printed circuit board assembly. This is a crucial element in the performance of any type of device, electronic component or system, and ensuring the board is designed to provide the performance required in the working conditions will be essential.

Design Services

Not all electronic contract manufacturers provide design services along with their printed circuit board assembly capabilities. By combining these two services, the OEM internal team can work with the contract manufacturer to design a fully customized board in much less time than the in-house team could do on their own.

Additionally, by working with the contract manufacturer and making possible adjustments to the board design, it may be possible to significantly reduce the costs of the production of the board without altering performance and features.

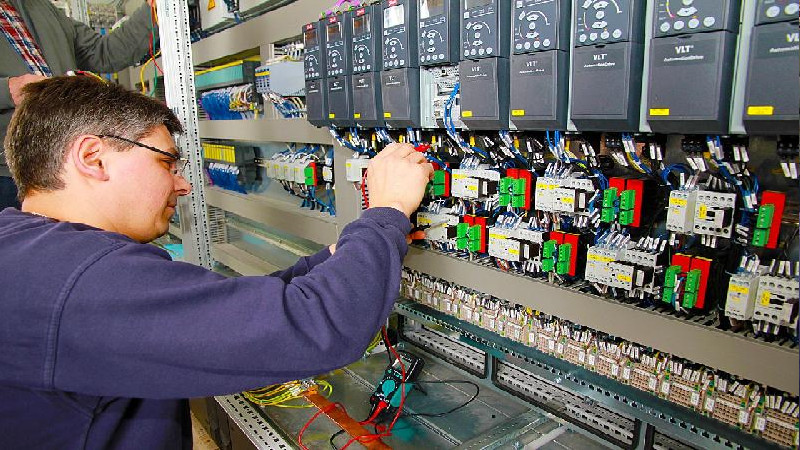

Some manufacturers will also offer a host of associated services including full engineering design, cable harness assemblies, and even electromechanical box build services.

Order Volume Requirements

In addition to the services offered by the contract manufacturer, be sure to consider any minimum or maximum volume restrictions or requirements. Think of the long-term production requirements needed and verify the company selected will be able to scale up production as needed to accommodate orders in the future.

Price, delivery reliability and the willingness to work to the requirements of the OEM are also important factors to look for when hiring electronic contract manufacturer for printed circuit board assembly and related services.