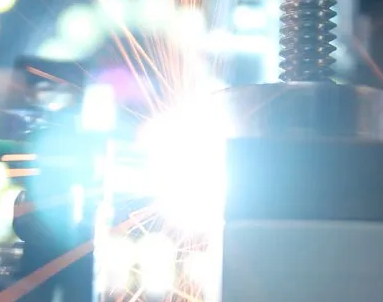

Capacitor discharge stud welding, or more simply known as CD stud welding, is an extremely fast and efficient way to attach studs to one base piece to allow for quick mating with another piece of the same or different metal or material.

Options To Consider

There are different options in capacitor discharge studs available. This includes the actual style or design of the stud as well as the material. In general CD studs are used with thinner base metals, allowing for a very fast weld without any marring, burning or distortion of the other side of the base metal.

CD stud welders are designed to work with capacitor discharge studs that are less than 3/8 of an inch in diameter. The thread pitch will be designed to match the diameter of the stud.

CD studs can be made from mild steel, stainless steel or aluminum. These are the standard materials most stud welding suppliers will offer. Specialized companies offering stud welding equipment and supplies will offer these standard materials in weld studs, as well as customized options made to meet the needs of a specific application. This is true for both threaded and non-threaded weld studs.

Consider Equipment and Supplies Together

For a single order of capacitor discharge studs for a one-time project, there is limited need to find a specialized provider unless there is a need for a custom size or type of CD stud.

Original Equipment Manufacturers and fabricators with a steady demand for low to high volume supplies of both CD studs as well as stud welding equipment will find there is an advantage to buying from a specialized company.

Lower prices, customized weld studs, equipment and even customer support and service and repairs are all things to consider when choosing a supplier and placing the first order.