For organizing and managing large or small cable and wire, the use of the right cable tie mounts is an important choice. When the walls or structures where the cable needs to run are metal, choosing metal cable tie mounts and using a stud welding process to secure them in place is fast, effective and long-lasting.

Fast Installation Processes

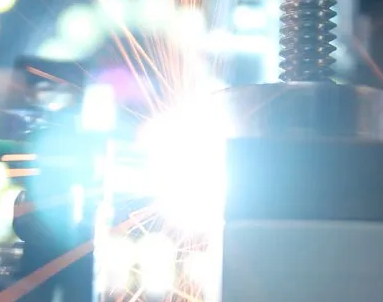

There are differences in the option for metal cable tie mounts based on the types of application method. Stud welding allows for a quick application, with many different types of the mounts able to be installed in about three seconds. The actual welding time is typically between 0.2 and 0.45 seconds, which means that the workpiece is not heated other than the very small covered weld area, meaning no marring or discoloration.

Without the need to drill holes and use bolts or screws to hold the cable mounts in place, this is a single step operation instead of a two or three step operation. Faster installation and more durable welds are possible when quality metal cable tie bases are selected.

Securing and Protecting the Cable

Different design features in metal cable tie mounts can be instrumental in securing and protecting the cable both during installation as well as after it is in place. Coined edges on the wings and sides of the mounts will prevent abrasion of the cable on the mount if there is vibration in the area.

Other features to look for include anti-roll out wings, which hold the cable in place and allow for a quick plastic tie to be used to secure the cable to the mount. This ability to lock the cable in the mount is also helpful to prevent abrasion from vibration or if the cable is ever pulled or caught anywhere along the run.