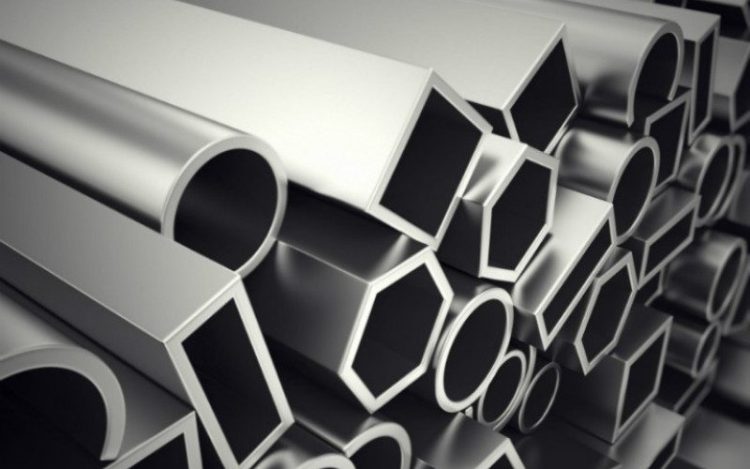

Aluminum extrusion is a means through which a company can transform the metal into objects possessing a specific cross-sectional profile. Custom aluminum extrusion is the hiring of the company to produce the aluminum in accordance with exact specifications. The extrusion process is favored for many reasons. Of particular importance is the technique’s ability to utilize the various positive qualities of aluminum.

Early History of Aluminum and Aluminum Extrusion

Aluminum is one of the world’s most abundant metals. It ranks third in this category. Yet, aluminum was not discovered until 1807 by a Baronet, Sir Humphrey Davy (1778-1879). It was relatively ignored until 1825 when physicist Hans Christian Oersted (1777-1851) produced pure aluminum. During that period, aluminum was perceived as a rare metal – for employment in luxury goods only.

This changed in the late 1880s. In 1886, two men – Charles Martin Hall and Paul Héroult independently invented the Hall-Héroult smelting process. Together with the move towards commercial production of various metals and products, aluminum became a viable metal for mass production. During this period, people rolled, cast and forged iron. Metal extrusion had been part of a process started in the late 18th century. Iron pipes were made through extrusion. However, aluminum products were not.

The Development of Aluminum Extrusion

In 1894, Alexander Dick invented what has come to be considered the modern method of extrusion – the hot extrusion process. It is now synonymous with aluminum. The first North American commercial employment of an aluminum extrusion press took place in 1905 for Alcoa in Massena. The press only remained briefly there before being relocated to the company’s New Kensington, Pennsylvania works.

During this century, the discoveries of such things as aluminum alloy’s heat treatability resulted in an increased interest in the material for more extensive projects. World War I saw aluminum (Duralumin) employed in the construction of airships for Germany. Both World Wars lead to further advances in aluminum technological as well as an increase in usage. Aircraft, automobile and construction all began to employ aluminum. The preferred method of production was aluminum extrusion. Custom aluminum extrusions became a common component of certain projects.

Custom Aluminum Extrusions, Today

Extrusion is the most common method of transforming aluminum. Companies can employ hot or cold methods. Aluminum extrusions are responsible for a large percentage of the market in both Europe and North America. The custom aluminum extrusions market is smaller but is indicative of how far the metal, its production methods and its usage have come.