Rigging equipment comes in various types, including wire ropes, sling shackles, master links, and lifting magnets. Specifically, Crosby lifting equipment is used to carry out rigging tasks in a safe manner, such as those related to material handling and the relocation of structures.

A variety of parts and devices are combined together to form different types of rigging equipment. This equipment is used to execute lifting tasks within a range of different industries, including manufacturing, construction, mining, pipelining, and oil and gas.

Powerful Lifting Equipment

As it concerns the development of Crosby lifting equipment, safety is of prime concern. This equipment uses high quality materials such as carbon, alloy, and high tensile steel in order to meet the requirements of various applications and specifications. The various types of rigging equipment and associated hardware available include:

* Eye bolts

* Hooks, shackles and swivels

* Crosby IP clamps

* Wire rope end fittings

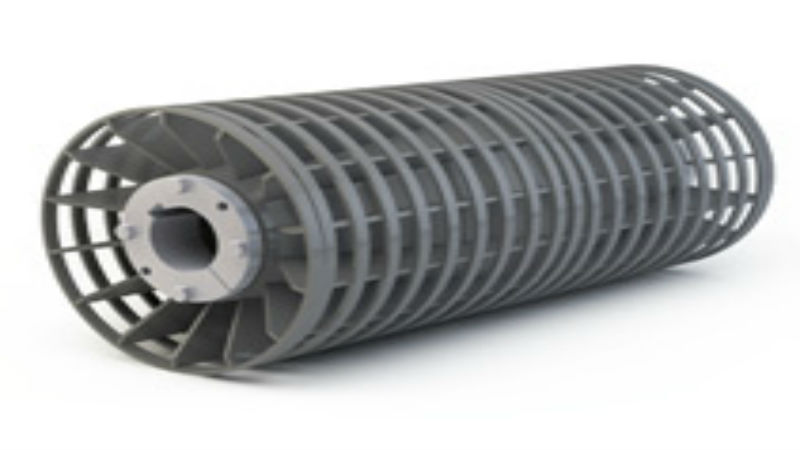

* Blocks and sheaves

* Chains and accessories

* Grip clips and wire rope clips

* Western and marine blocks

* Swivel hoists

Equipment That Use Rigging Hardware

Crosby rigging equipment utilizes hardware in order to facilitate the relocation of heavy loads, including plate, pipes, and beams. Various types of machines are capable of handling these heavy rigs through the use of rigging hardware – these include recovery vehicles, overhead shop cranes, mobile crane trucks, personal jib cranes, and winches.

Other Benefits

Other than the various types of Crosby lifting hardware and accessories that are used within the rigging industry, other resources are also available to consumers in order to improve overall rigging efficiency. These include: manuals and brochures for product info, specialty products for unique specifications and user requirements, rigging information, on-site inspection, and hardware and equipment repair.

As mentioned above, the rigging industry utilizes Crosby lifting equipment and rigging hardware extensively on numerous projects. Many of the most difficult reading projects can be handled efficiently and effectively through the use of this high quality rigging equipment. When it comes to lifting and rigging operations, it is of vital importance that those responsible for these operations follow all code requirements and safety standards, from planning and preparation to the actual performance of the operation.