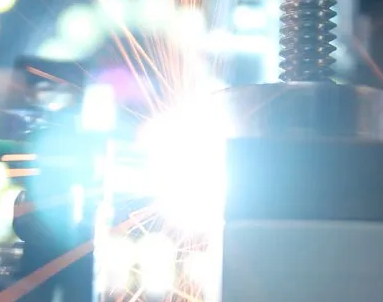

Anytime a welding company has to weld together very tiny pieces, a micro-arc welding machine is often used. Often, a percussion welder is used, which combines mechanical “percussive” movement with a heat-generating micro-arc. This is the perfect combination if what you want is a fast and easily controlled way to weld, and it’s great for welding together very small pieces of metal that will eventually end up in products such as medical devices, electronic equipment, and even auto parts and similar items.

Why Is This Type of Machine So Efficient?

A high-tech micro-arc welding machine offers numerous advantages. For one thing, it can be used to weld together many different types of metal, including brass, steel, copper, and titanium, among others. You can also weld without worrying about the metals you’re working with getting too soft, and you can even weld metals that are dissimilar.

With a low application of pressure and a minimum heat-affected zone, you rarely have to solder or crimp simply because it is an autonomous weld, regardless of what you’re making.

These Machines Can Be Miracle Workers

When it comes to welding, your tools and equipment are everything. Without the right equipment, you’re limited in the jobs you can do, but if you’re interested in creating tiny or delicate items for any industry, a micro-arc welding machine is what you want. The machines are user-friendly and can accommodate all types of items. Once you find a company that sells them, they’ll answer all of your questions and teach you what you need to know to operate them efficiently.