CNC plastic machining makes it possible to reliably and affordably manufacture custom plastic components for a variety of industries. These components are frequently used in scientific, medical, and food industries, among others. As a matter of fact, many of the plastic items you use or touch on a daily basis may have been manufactured in some degree using CNC machining.

There are those who argue against plastic machining, but it happens to be one of the best manufacturing techniques used in modern times. Here are three of its key benefits.

1. Extreme Precision

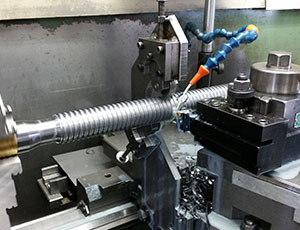

Modern CNC plastic machining devices are extremely precise. They can craft custom components that are extremely small with a variety of different angles and threading styles. The degree of precision will vary from company-to-company according to the expertise of their engineers and the quality of their machines. Nonetheless, it’s usually a competition to see who can be the most precise and the clients always win.

2. Increase Affordability

Using custom plastic components increases affordability in multiple ways. Primarily, the use of plastic is cheaper than alternatives like steel or aluminum. Obviously, there are some applications where those metals would be necessary, but if a high-quality plastic is capable of handling the workload, then it’s the most economical option.

3. Digital Efficiency

Finally, the error-free efficiency of the computerized CNC platform is a huge benefit. Less time is spent correcting errors and sending products back to the manufacturing company. That means time and manpower is spent on more important aspects of running a business.

The Obvious Choice

CNC plastic machining components are seen in so many places that it’s obvious it must work and it must be efficient. In addition to that, the components can be manufactured to precision according to complex specifications and without costing an arm and a leg. Overall, it’s an obvious manufacturing choice for processes where plastic can handle the job.